Top Strategies for Convenience Store Storage Tank Maintenance

Convenience store storage tank maintenance is essential for safety and efficiency. This guide covers regular inspections, leak detection, and corrosion protection. Discover how to prevent problems and stay compliant with regulations.

Key Takeaways

Understanding the characteristics and maintenance requirements of aboveground and underground storage tanks is essential for effective fuel tank maintenance.

Implementing regular inspections, leak detection methods, and corrosion protection measures can significantly extend the lifespan of fuel storage tanks and ensure compliance with safety regulations.

Cost-effective maintenance strategies, such as utilizing multicompartment tanks and scheduling routine fuel deliveries, enhance operational efficiency and reduce the risk of contamination.

Understanding Fuel Storage Tanks

Fuel storage tanks in convenience stores are generally classified into aboveground storage tanks (ASTs) and underground storage tanks (USTs), each with distinct characteristics and maintenance requirements. ASTs are often favored because they are easier to maintain, more accessible, and have a lower regulatory burden compared to their underground counterparts.

However, USTs are still widely used despite posing significant challenges, such as leak detection difficulties and expensive cleanup operations. Proper placement of these tanks is crucial, with specific distances mandated from buildings and water sources to mitigate potential safety hazards.

Many convenience store chains opt for large, double-wall tanks for enhanced safety. These tanks provide an additional layer of protection against leaks, ensuring that any fuel that escapes the primary wall is contained within the secondary wall. This dual-layer design is particularly important for USTs, given the potential environmental disasters associated with leaking tanks.

Understanding the different types of storage tanks and their respective benefits and challenges is the first step in effective fuel tank maintenance. Selecting the appropriate tank and placing it correctly can significantly minimize the risks tied to fuel storage for convenience stores.

Key Maintenance Practices for Convenience Store Fuel Tanks

Maintaining fuel tanks properly ensures clean fuel, prevents downtime, and reduces costly repairs. This requires following correct storage and maintenance practices and adhering to local ordinances.

Year-round maintenance is needed to maintain high-quality fuel and ensure the operational status of fuel tanks.

Regular Inspections

Regular inspections help identify issues like leaks or corrosion early on, ensuring the tank’s integrity and limiting contamination. Routine checks also maintain tank integrity and fuel quality. Regularly inspect fire safety equipment around tanks to ensure it is ready in case of an emergency.

Consistent maintenance procedures can greatly extend the lifespan of underground storage tanks and reduce replacement costs. This proactive approach minimizes leak risks and environmental hazards.

Leak Detection Methods

Employing various leak detection methods ensures the safety and integrity of UST systems. Interstitial monitoring, a required leak detection method for hazardous substance USTs, involves maintaining a confined space between the primary and secondary walls of the tank. This method, along with secondary containment, is mandatory for UST systems installed or replaced after April 11, 2016.

Regular maintenance extends the lifespan of fuel tanks by identifying issues early. Proper monitoring practices reduce the risk of costly leaks, ensuring a safer and more efficient fuel storage system.

Corrosion Protection

Corrosion protection maintains the integrity and longevity of fuel storage tanks. Cathodic protection, which uses electrical currents to prevent corrosion, is vital for extending the lifespan of underground storage tanks. Regular cleaning of fuel tanks also helps prevent corrosion and extends their operational lifespan.

Besides cathodic protection, regular cleaning and maintenance are necessary to prevent corrosion and ensure the longevity of storage tanks. These practices are integral to maintaining a safe and efficient fuel storage system.

Preventive Measures for Fuel Tank Maintenance

Preventive measures are crucial in maintaining fuel storage tanks and preventing costly repairs and potential safety hazards. By implementing these strategies, convenience stores can enhance fuel quality and operational efficiency.

Ensuring Proper Ventilation

Proper ventilation prevents the accumulation of explosive vapors in fuel storage tanks and maintains fuel quality. Properly designed vents help prevent pressure buildups that can lead to tank damage. Regular checks and maintenance of venting systems ensure they are free from blockages and functioning properly.

Effective air exchange reduces the risk of vapor buildup, which can lead to explosions. Convenience stores should install venting systems that are adequately sized and positioned to ensure proper ventilation and safety.

Managing Water Buildup

Water buildup in fuel tanks can lead to sludge formation and compromise fuel quality. Regularly draining water from tanks maintains fuel quality and prevents sludge formation. Desiccant breathers can significantly reduce moisture intrusion in fuel tanks.

Implementing these strategies will enhance fuel quality and operational efficiency in convenience store storage tank maintenance. Effectively managing water buildup ensures the longevity and reliability of fuel storage systems at convenience stores.

Fire Safety Precautions

Fire safety is paramount when dealing with fuel storage tanks. Fuel storage tanks need to have a fire-guard or vault that can withstand ignition for at least two hours in case of a fire. However, this requirement doesn’t apply if the flashpoint is higher than 100 degrees Fahrenheit. Fire extinguishers should be located near aboveground storage tanks to ensure quick access in case of a fire.

Keeping the area around storage tanks and the surrounding soil free of weeds and grasses reduces fire hazards. Vegetation around an AST can pose fire hazards, disguise leaks, damage the containment floor, and accelerate corrosion.

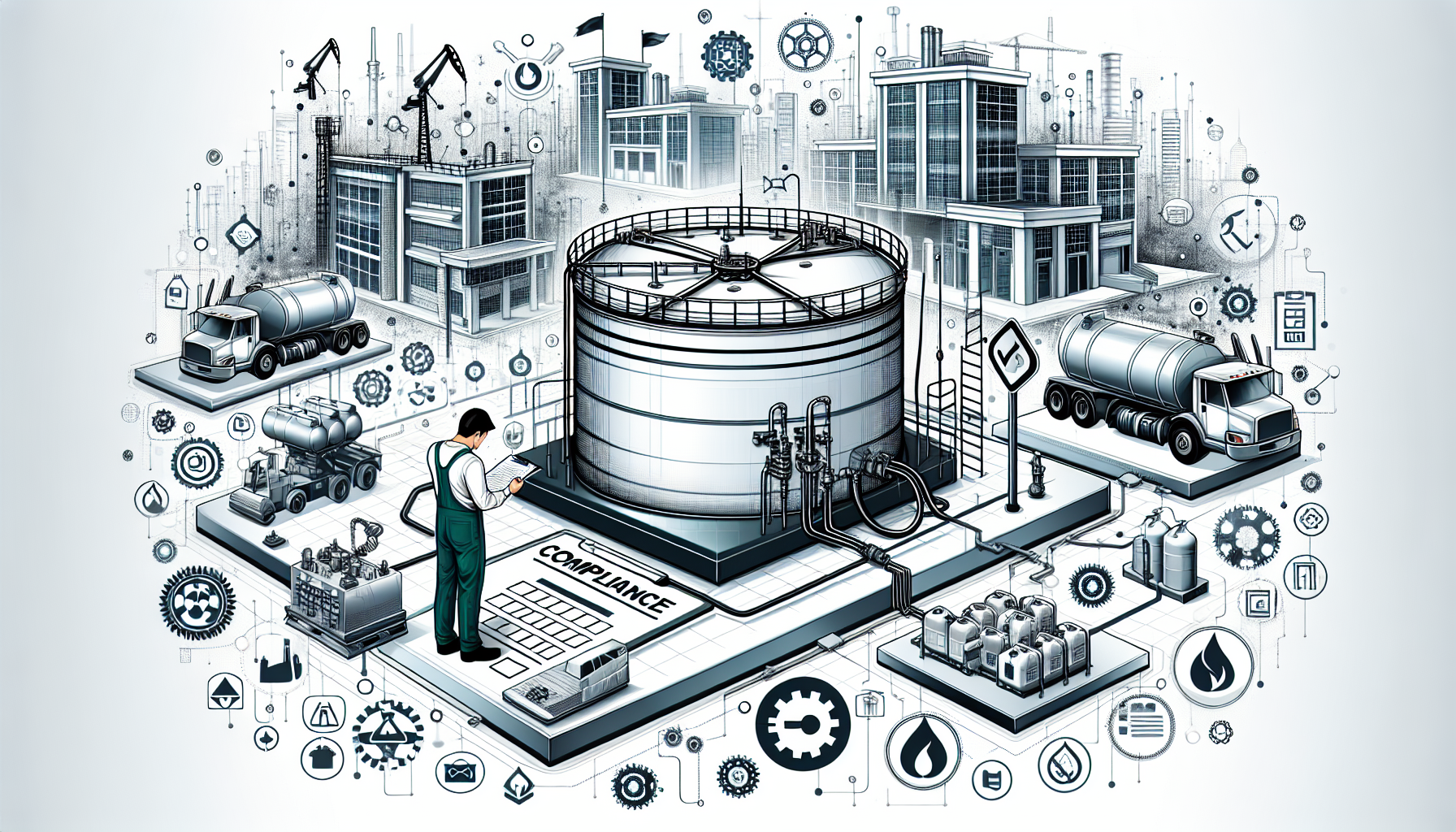

Compliance with Regulations

Adhering to federal and local regulations ensures the safe and efficient operation of fuel storage tanks. Regular inspections and adherence to local ordinances ensure compliance and protect the environment.

Following Federal UST Requirements

Federal regulations mandate frequent inspections and reporting for underground storage tanks (USTs) to ensure environmental compliance. The EPA’s regulations concerning USTs include technical requirements and state program approval objectives to safeguard health and the environment. The Underground Storage Tank Program aims to protect human health. It also focuses on safeguarding the environment by preventing releases from UST systems.

Secondary containment encloses a UST within a second wall to contain and detect leaks effectively. Investing in a double-walled tank or including a secondary containment area prepares for potential leaks. Hazardous substances USTs are subject to the same secondary containment requirements as petroleum USTs.

Federal and state laws mandate training for UST operators, ensuring compliance and safety during operation. Warning signals that indicate a leak in an underground storage tank include unexplained fuel loss and changes in product levels. If a UST release is suspected, immediately notify your state or local agency or the EPA regional UST program office.

Adhering to Local Regulations

Understanding local regulations is crucial as they vary by state or municipality. Local regulations may impose additional requirements beyond federal standards for UST systems. Many USTs were upgraded to meet regulations imposed in 1988, but many are still not updated, complicating compliance. The UST technical compendium provides valuable insights into these regulations.

Understanding and adhering to local regulations ensures compliance and helps avoid fines and environmental hazards for convenience stores. Regular inspections and proper maintenance are vital for meeting these regulatory requirements.

Cost-Effective Maintenance Solutions

Cost-effective strategies help maintain fuel storage tanks without breaking the bank. These approaches ensure compliance and prepare for the future while maintaining existing assets and fueling system components.

Utilizing Multicompartment Tanks

Multicompartment tanks are crucial for convenience stores as they enable the simultaneous storage of different liquids in a single unit. They reduce costs for convenience stores without needing an expensive double-wall bulkhead upgrade, making them financially advantageous. Allowing the storage of multiple fuel types in a single unit, multicompartment tanks save valuable space and reduce operational costs.

These tanks enhance efficiency and reduce the risk of contamination between different fuel types. Multicompartment tanks offer a smart and cost-effective solution for optimizing fuel storage systems in convenience stores.

Scheduling Routine Deliveries

Maintaining an adequate fuel level in storage tanks prevents operational disruptions. The recommended minimum fuel level for tanks is 80%. Pre-scheduling fuel deliveries ensures uninterrupted daily operations and helps maintain fuel quality.

Scheduling routine deliveries helps convenience stores avoid running low on fuel and ensures a steady supply for customers. This proactive approach maintains operational efficiency and enhances customer satisfaction.

Emergency Response and Spill Prevention

Emergency response protocols manage incidents involving fuel storage tanks. Preparing for emergencies involves securing fuel storage tanks and ensuring emergency response equipment availability.

Preparing for Natural Disasters

Securing fuel storage tanks mitigates risks during natural disasters. Ensuring these tanks are protected prevents damage and potential leaks.

Spill Prevention Control and Countermeasure (SPCC) Plan

A comprehensive Spill Prevention Control and Countermeasure (SPCC) plan is crucial for effectively responding to fuel spills and minimizing environmental impact. In case of suspected leaks in USTs, immediately contact the implementing agency and report the suspected leaks. After confirming a UST release, respond in two stages: short-term actions to mitigate immediate risks and long-term strategies for addressing the underlying issues.

A well-structured SPCC plan ensures convenience stores are prepared to handle spills effectively, minimizing risks to public health and the environment.

Professional Maintenance Services

Hiring professional maintenance services ensures compliance with regulations and optimal performance of fuel storage tanks.

Hiring Certified Technicians

Certified technicians handle maintenance tasks, ensuring they are performed by qualified professionals. Proper certification allows technicians to handle specialized equipment safely and effectively, reducing the risk of equipment failure due to professional handling and maintenance.

Certified professionals reduce errors during maintenance, enhancing the overall reliability of UST systems for ust owners. Utilizing certified technicians leads to better compliance with regulations and improved storage system performance.

Regular Cleaning and Treatment

Regular cleaning of fuel tanks maintains the integrity of stored fuel and prevents contamination from debris and microbial growth. Cleaning and treating fuel tanks significantly reduce the risk of microbial contamination. The cleaning process for ASTs includes draining fuel, removing sludge, scrubbing, rinsing, and drying. This regular practice ensures fuel performance, minimizes safety hazards, and extends the lifespan of the tank.

Diesel fuel biocides or other additives can treat bacteria in fuel tanks, preventing microbial growth that causes tank corrosion, clogged filters, and reduced fuel performance. Regular cleaning enhances fuel efficiency by using additives that disperse water and stabilize fuel.

Fuel that is not properly cleaned can damage engines or generators, making this maintenance task critical for operational efficiency.

Summary

In summary, maintaining fuel storage tanks in convenience stores involves a combination of regular inspections, leak detection, corrosion protection, preventive measures, compliance with regulations, cost-effective solutions, emergency response, and professional services. By implementing these strategies, convenience stores can ensure the longevity and reliability of their fuel storage systems, ultimately enhancing operational efficiency and safety. Investing in proper maintenance practices not only protects the environment but also ensures a steady supply of high-quality fuel for customers.

Frequently Asked Questions

What are the main types of fuel storage tanks used in convenience stores?

The primary types of fuel storage tanks utilized in convenience stores are aboveground storage tanks (ASTs) and underground storage tanks (USTs). Each type serves to meet specific regulatory and operational requirements.

Why are regular inspections important for fuel storage tanks?

Regular inspections are essential for early detection of leaks or corrosion, which helps maintain the integrity of fuel storage tanks and ensures the quality of the fuel. Neglecting these inspections can lead to significant safety and environmental risks.

What is interstitial monitoring in leak detection methods?

Interstitial monitoring is a reliable leak detection method that utilizes a confined space between the primary and secondary walls of a tank to effectively identify leaks. This approach enhances safety by allowing for prompt detection and response to potential leaks.

How can convenience stores manage water buildup in fuel tanks?

Convenience stores can effectively manage water buildup in fuel tanks by routinely draining accumulated water and employing desiccant breathers to minimize moisture intrusion. This proactive approach is essential for maintaining fuel quality and operational efficiency.

Why is it important to hire certified technicians for fuel tank maintenance?

It is crucial to hire certified technicians for fuel tank maintenance as they possess the necessary qualifications to ensure tasks are performed correctly, thereby minimizing equipment failure and improving the reliability of underground storage tank systems.